UA-612KZH CNC Six Side Drilling Machine Manufacturers

Parameters

|

Model |

UA-612KZH |

|

|

Each axis stroke & Maximum positioning speed |

X axis |

5000mm & 100m/min |

|

Y axis |

1200mm & 80m/min |

|

|

Z axis |

90mm & 30m/min |

|

|

U axis |

1200mm & 60m/min |

|

|

V axis |

1200mm & 80m/min |

|

|

W axis |

60mm & 30m/min |

|

|

A axis |

5000mm & 100m/min |

|

|

Y2 axis |

1500mm & 80m/min |

|

|

Z2 axis |

90mm & 30m/min |

|

|

Processing size range |

Maximum plate width |

1200mm (without side milling) |

|

850mm (with side milling) |

||

|

Minimum plate width |

35mm (without side milling) |

|

|

50mm (with side milling) |

||

|

Minimum plate length |

150mm (without side milling) |

|

|

400mm (with side milling) |

||

|

Maximum plate thickness |

50mm |

|

|

Depth processing range |

Drilling: 0-45mm |

|

|

Side milling: X(45mm), Y(65mm) |

||

|

Dust suction flow |

7300m³/h |

|

|

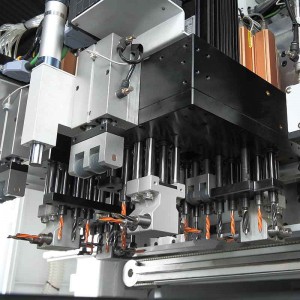

Upper drilling combination configuration |

Vertical drilling |

Upper drill: 12 pcs |

|

Horizontal drilling |

Horizontal drill: 8 pcs |

|

|

Drilling unit motor speed |

3400rmp(r/min) |

|

|

Upward milling spindle/power |

1x6kW (automatic tool change + 4-position tool magazine) |

|

|

Side milling motor power |

1x6kW |

|

|

Downward milling spindle/power |

1x3.5kW |

|

|

Spindle type |

ISO 30/Er32 Lower spindle: Er25 |

|

|

Lower drilling combination configuration |

Vertical drilling |

Drill-down: 9 (3x3 matrix distribution) |

|

Drilling motor power |

2.2kW |

|

|

Downward milling spindle/power |

1x3.5kW |

|

|

Spindle type |

Er25 |

|

|

Other |

Workbench height |

950mm |

|

Total power |

23kW |

|

|

Operating Voltage |

380V/50Hz |

|

|

Working air pressure |

0.7-0.8Mpa |

|

|

Dimensions |

5800x2840x2200mm |

|

|

Total weight |

About 3800kg |

|

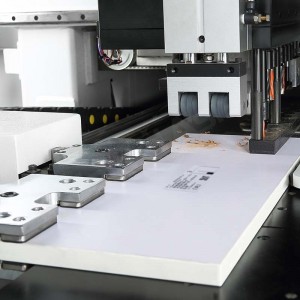

Introduction

INDEPENDENT CROSS-ROTATING SIDE MILLING, AUTOMATIC TOOL CHANGE WITH SERVO FOUR-TOOL MAGAZINE

ONE MACHINE MEETS MULTIPLE PROCESS REQUIREMENTS, A MUST-HAVE TOOL FOR CUSTOM FURNITURE

- Double drill package (upper 1 + lower 1), three spindles (upper 2 + lower 1), four-position tool magazine, four-sided side milling.

- The equipment can be equipped with a variety of tools of different shapes and sizes and drill bits of different specifications, which can complete the six-sided milling and drilling of the workpiece at one time, and efficiently solve various milling and drilling process problems!

- Mainly used in furniture manufacturing processes such as Lamino, invisible parts, side milling functions, lamp line troughs and ceiling hinges.

- The minimum width of the plate that can be processed for punching is 35mm, which is a unique advantage.

Capacity Report

- For pure six-sided punching, the number of plates is 700-800 pieces per day for 8 hours (punching and grooving).

- For mixed five-sided and six-sided punching, the number of plates is 800-1000 pieces per day for 8 hours (punching and grooving).

- For pure five-sided punching, the number of plates is 1000-1100 pieces per day for 8 hours (punching and grooving).

- For pure five-sided punching, the number of plates is 1100-1200 pieces per day for 8 hours (punching only).