UA-612KJ CNC Six Side Drilling Machine Factories

Parameters

|

Model |

UA-612KJ |

|

|

Processing size |

Plate width |

35-1200mm (35-50mm L≤1000mm) |

|

Plate length |

70-2800mm |

|

|

Plate thickness |

9-50mm |

|

|

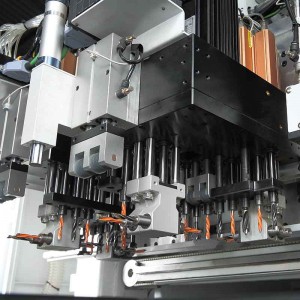

Top drill box |

Vertical drill |

12 |

|

Horizontal drill |

8 |

|

|

Longitudinal saw blade |

1 |

|

|

Motor speed |

3400rpm(r/min) |

|

|

Bottom drill box |

Vertical drill |

3x3 |

|

Motor speed |

3400rpm(r/min) |

|

|

Milling spindle |

Power |

2x3.5kW |

|

Type |

Er25 |

|

|

Handle diameter |

1/2 shank diameter |

|

|

Speed |

18000rpm(r/min) |

|

|

Feeding table |

Type |

Air flotation table |

|

Height |

950mm |

|

|

Discharge table |

Type |

Drum |

|

Height |

950mm |

|

|

Working Parameters |

Total power |

20.05kW |

|

Working voltage |

380/50V/Hz |

|

|

Working air pressure |

0.7-0.8Mpa |

|

|

Working time per week |

7x24 Day/H |

|

|

Vacuum outlet |

Diameter |

1 x 150mm 1 x 100mm |

|

Flow rate |

7300m³/h |

|

|

Machine |

Dimensions (LxWxH) |

5050X2790X2200mm |

|

Weight |

3510kg |

|

Introduction

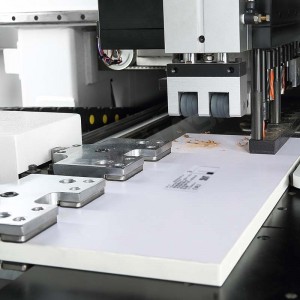

SIX-SIDED DRILLING, DOUBLE-SIDED SLOTTING, MILLING PROCESSING

NEWLY UPGRADED, INTELLIGENTLY OPTIMIZED PROCESSING PATH

- The first-class six-sided drilling technology can easily realize the drilling of six sides of the plate, the slotting or milling of the upper and lower sides, and the opening of hinge holes. It is a drilling equipment that focuses on high-precision drilling and efficient output. It is a processing tool for custom furniture factories and cabinet production.

- Complete the six-sided drilling and front and back slotting of the plate at one time.

- Equipped with two CNC-controlled clamps, it can clamp and accurately position the workpiece permanently.

- It can not only operate as a single machine, but also can be connected to multiple machines or even combined with other drilling CNCs to achieve efficient automation of the drilling process.

- Scan code processing - scan the code to read the processing program, no programming and debugging are required.

- Minimum processing size - can be as small as 70mm (length) X 35mm (width).

- Each hole can be drilled with extremely high repeatability, and the same is true for milling and slotting. Despite the extremely fast movement speed, the workpiece surface can still be perfectly protected.

- Automatic thickness inspection and length measurement to achieve reliable processes.