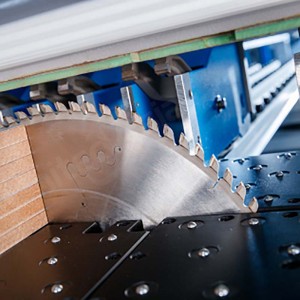

MJ270 Computer Beam Saw Machine For Wood Cutting

Details

- The side aligner adopts dual intelligent modes, which can be switched automatically.

- It adopts a flexible rubber-wrapped double-finger structure, and the minimum splint size can be 34x45mm.

- The main saw and the auxiliary saw adopt an independent lifting control system, which can automatically position the sawing stroke according to different sawing heights and widths, reduce the idle stroke time, and improve work efficiency.

- The work surface adopts a pneumatic float table to effectively prevent the board from being scratched, and the board is easier to move.

Parameters

|

Model |

MJ270 |

|

Maximum sawing length |

2680mm |

|

Maximum sawing thickness |

120mm |

|

Main blade diameter |

Φ350-450mm |

|

Main saw blade shaft |

Φ75mm |

|

Main blade speed |

4800m/min |

|

Secondary saw blade diameter |

Φ200mm |

|

Secondary saw blade shaft |

Φ50mm |

|

Secondary saw blade speed |

7000m/min |

|

Saw cutting speed |

0-100m/min |

|

Overall size(L x W x H) |

5356x5950x1890mm |

|

Saw back speed |

0-120m/min |

|

Main saw drive motor |

15kw |

|

Secondary saw drive motor |

2.2kw |

|

Saw seat servo drive |

2kw |

|

Feed servo motor |

2kw |

|

High pressure air supply motor |

2.2kwx2 |

|

Automatic feeding speed |

0-120m/min |

|

Use air pressure |

6-8Mpa |

Introduction

Are you troubled by further improving the optimal utilization of panels? Are you still bothered by the time-consuming and labor-intensive manual input? Use our MJ270 beam saw to solve these problems. The MJ270 beam saw uses precision electrical components to enable the electronic saw to run at high speed. Computer automatic command makes the cutting process simple and convenient, greatly improves the processing precision, and significantly improves the safety factor. Even a novice can perform human-machine integration after training. The operation is convenient. The MJ270 beam saw has a high-performance feeding clamp device, which is driven and positioned by a precision servo. Gear rack transmission, CNC sawing. The sawing effect is good, and the end face of the plate is smooth and without burrs. The machine adopts high-quality process welding technology and annealing treatment to ensure the stability and service life of the equipment, which is safe and reliable. At the same time, it is suitable for cutting a variety of materials and is widely used. If you want to know more, please contact us for consultation!